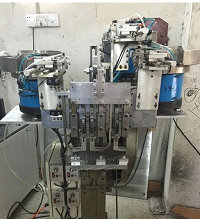

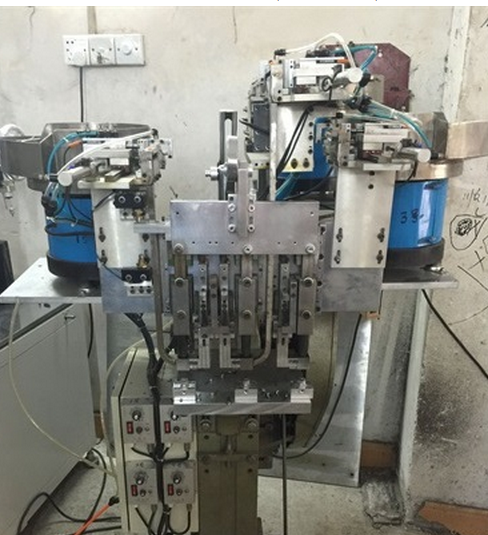

Ultrasonic plastic welding machines have evolved to the present and are diverse. How do consumers buy so many styles and brands of welding machines?

First, the choice of ultrasonic plastic welding machine output power:

The output power of the ultrasonic wave is determined by the diameter and thickness of the piezoelectric ceramic piece, the material, and the design process. Once the transducer is shaped, the maximum power is also fixed. Measuring the amount of output energy is a complicated process. The larger the transducer, the more power the circuit uses and the higher the output energy. It requires a fairly complex amplitude meter to accurately measure its amplitude.

Second, the requirements of ultrasonic plastic welding machine for welding workpiece materials:

Ultrasonic plastic welding machines are required for the material of the workpiece to be welded. Not all materials can be welded. Some people think that any material can be welded. This understanding is wrong. Different materials can be welded directly, some are basic phase fusion, and some are not phase fusion. The melting point between the same material is the same, and the principle is that it can be welded, but when the melting point of the workpiece to be welded is greater than 350 ° C, it is not suitable for ultrasonic welding. Since the ultrasonic is instantaneously melting the workpiece molecules, the judgment is based on 3 seconds, and the welding cannot be performed well, and other welding processes should be selected. Such as hot plate welding. Generally speaking, ABS material is the easiest to weld, and nylon is the most difficult to weld.

At present, various plastic parts using ultrasonic plastic welding machines have become quite popular, and become an essential equipment for clothing packaging, medical, electronic appliances, auto parts and other industries. When purchasing an ultrasonic plastic welding machine, I hope everyone can master the correct method!

相关标签: