Want to know what is the ultrasonic mold technology? It is necessary to consider the requirements of the following factors: to determine the service life of the mold, ultrasonic mold is one of the most technical depth of ultrasonic technology. Production of a set of ultrasonic molds. The rate of wear, which determines which metal to use.

First, the shape of the product: What kind of welding process is used, the size of the mold is set, the pressure transmission area, the deformation that may occur when the product is fused, how much power and function is required. Can you finish the work in one weld?

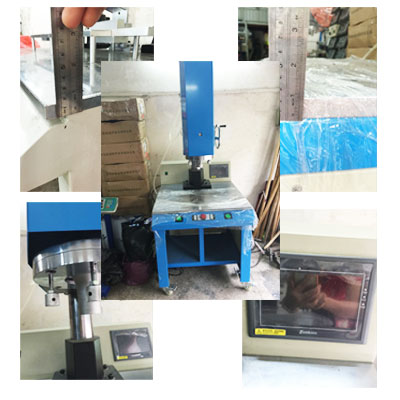

Second, the plastic nature of the product: determine the working amplitude of the mold, that work should accept the ultrasonic energy, the form of the energy guiding line, the size, size. How to design the contact position when different plastic combinations are used. Each set of welding heads and molds produced, whether it is a standard product or customized according to customer requirements, is made with the best materials and tested repeatedly. Various parameters such as the shape, strength and audio of the welding head have been tested several times to meet the most stringent specifications, and the welding head and the mold are perfectly matched.

Dongguan Yihui Machinery Equipment Co., Ltd. has been engaged in the ultrasonic industry for many years and its performance is relatively stable and mature. The welding equipment mainly adopts mature technology such as Taiwan's self-excited oscillation circuit, and the output is strong and stable, the protection is perfect, and it is sturdy and durable. The core components such as transducers are imported from Japan and West Germany, with long service life and excellent performance. It is a good helper for your production! Welcome to inquire!

相关标签: