1. When placing the automatic folding edge welding machine in Dongguan, do not be too far or too close, 1/2, proficiency.

2, heating the heat shrinkable sleeve, the process name is called the reinforcement of the joint part, when heating, the welded part must be placed in the middle, add a certain tension, to prevent bubbles in the heating process, insufficient fixation, etc., emphasize the heating process The welding process can be carried out at the same time. When heating out, do not touch the heated part, the temperature is high, to avoid danger.

3, cleaning the inside and outside of the automatic folding edge welding machine, the fiber itself, the important thing is the V-shaped groove, the fiber presser foot and other parts.

4. When finishing the tool, pay attention to the broken fiber head to prevent danger. The fiber is glass filament, very thin and very hard.

5. When cutting, ensure that the cutting end face of the welding machine is 89°±1°, which is approximately vertical. During the process of placing the cut fiber in the specified position, the end face of the fiber should not touch any place. If it is encountered, we need to clean and cut it again. Be sure to clean and cut first.

6. Do not open the windshield cover during the welding process of the fusion splicer.

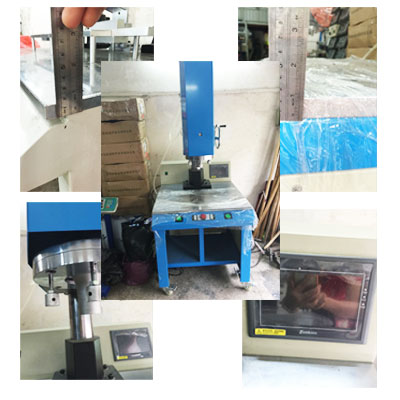

Dongguan Yihui Machinery Equipment Co., Ltd. has been engaged in the ultrasonic industry for many years and its performance is relatively stable and mature. The welding equipment mainly adopts mature technology such as Taiwan's self-excited oscillation circuit, and the output is strong and stable, the protection is perfect, and it is sturdy and durable. The core components such as transducers are imported from Japan and West Germany, with long service life and excellent performance. It is a good helper for your production! Welcome to inquire!

相关标签: