Nowadays, there are more and more types of mechanical equipment on the market. As a result, the ultrasonic plastic welding machine equipment has been continuously consolidated due to its performance advantages, and the leading of other industries has begun to fully develop. The manufacturing process of domestic ultrasonic plastic welding machine equipment is increasing, bringing a lot of convenience for more consumption. Here are the top ten advantages of ultrasonic plastic welding equipment:

First, high security

It adopts electronic program control, high degree of automation, easy operation, built-in electronic protection circuit, safe use, stable and reliable work.

Second, strong durability

Ultrasonic plastic welding machine welding tools are obtained by high-quality tool steel finishing, with excellent wear resistance, easy installation and high welding precision.

Third, cost savings

Consumables such as solder, flux, bends and brass are avoided, making ultrasonic welding the most cost-effective soldering technology.

Fourth, high reliability

Welding equipment monitors time, energy, power and high limits to ensure excellent process control, ensure welding accuracy, vertical (non-fan) pressurization system, two welded objects overlap, and ultrasonically pressurize and join into solid connection, joint time The short joint portion does not produce a defect in the cast structure (rough surface), the weld position is uniform, and the adjustment is simple.

Fifth, the mold life is long

Compared with the resistance welding method, the mold has a long service life, less mold repairing and replacement time, and is easy to automate.

Sixth, low temperature

Ultrasonic welding minimizes the temperature effect of the material (the temperature of the weld zone does not exceed 50% of the absolute melting temperature of the workpiece to be welded), so that it does not change the structure of the workpiece, so it is suitable for welding applications in the electronics field.

Seven, high efficiency and automation

The typical welding time is less than 0.5 seconds, the size is small, the maintenance workload is small, and the adaptability is strong, making the ultrasonic equipment the first choice for the automated assembly line.

Eight, low energy consumption

In terms of energy consumption, ultrasonic welding can be performed between the same kind of workpiece and different kinds of workpieces, and the energy consumption is much less than that of electric welding.

Nine, welding of dissimilar materials

Ultrasonic welding can also be processed for different types or similar workpieces (such as nylon + PP material, plastic + non-woven fabric, materials of different plastic materials, etc.).

Ten, convenient welding

Ultrasonic welding requires no external factors such as flux, glue, plastic filler, external heating. In most cases, the ultrasonic plastic welding machine sends high-frequency signals through the sounder, vibration friction is transmitted to the interface, and the interface melts rapidly.

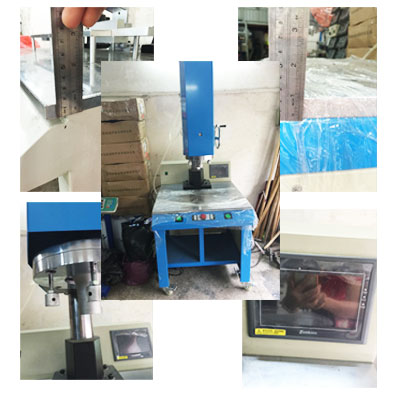

Dongguan Yihui Machinery Equipment Co., Ltd. has been engaged in the ultrasonic industry for many years and its performance is relatively stable and mature. The welding equipment mainly adopts mature technology such as Taiwan's self-excited oscillation circuit, and the output is strong and stable, the protection is perfect, and it is sturdy and durable. The core components such as transducers are imported from Japan and West Germany, with long service life and excellent performance. It is a good helper for your production! Welcome to inquire!

相关标签: