Ultrasonic plastic welding machines are used more and more. Most manufacturers who often use ultrasonic plastic welding machines will encounter cracks in some products. I don’t know if you have thought about the reasons for this phenomenon. How to solve it? It’s okay to think about it. Today, Yihui will bring everyone to discuss the reasons and solutions for the cracks in the ultrasonic plastic welding machine. Interested friends can look at it.

There are scratches or cracks on the surface of the product. In ultrasonic welding, it is common for the surface of the product to be scratched, broken or cracked at the joint.

Because there are two situations in an ultrasonic operation:

1. High thermal energy directly contacts the surface of plastic products

2. Vibration conduction.

Therefore, when the ultrasonic vibration acts on the plastic product, the surface of the product is prone to burns, and the plastic column or hole with a thin thickness of 1 m/m is also prone to cracking. This is a prerequisite for ultrasonic operation. Avoided. On the other hand, due to the lack of ultrasonic output energy (extension table and HORN upper mold), it takes a long time to weld when the vibration friction energy is converted into heat energy, so as to compensate for the insufficient output power by accumulating heat energy. This kind of welding method is not the vibration friction heat energy that is achieved in an instant, but the welding time is required to accumulate the heat energy, so that the melting point of the plastic product reaches the welding effect, so that the heat energy stays on the surface of the product for too long, and the accumulated temperature And stress will also cause burns, breaks or breaks in the product. Therefore, it is necessary to consider the power output (number of segments), welding time, dynamic pressure and other factors to overcome this type of job loss.

Solution:

1. Reduce the pressure.

2. Reduce the delay time.

3. Reduce the welding time.

4. Reference media coverage.

5. The mold has a surface treatment.

6. The number of machine stages is reduced or reduced.

7. For products that are easily cracked or broken, the fixture should be made of cushioning, such as soft resin or covered cork (this means does not affect the welding strength).

8. Easy to break products add R angle at right angles.

Seeing here, I believe that everyone has already understood the reasons for the occasional cracks in the products when using the ultrasonic plastic welding machine, but the solution is remembered? Ok, today's Xiaobian article content is here. If you have any questions, please contact us directly. I will have more exciting articles to update. You can look forward to it. .

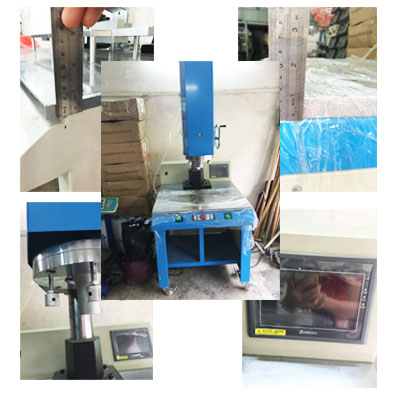

Dongguan Yihui Machinery Equipment Co., Ltd. has been engaged in the ultrasonic industry for many years and its performance is relatively stable and mature. The welding equipment mainly adopts mature technology such as Taiwan's self-excited oscillation circuit, and the output is strong and stable, the protection is perfect, and it is sturdy and durable. The core components such as transducers are imported from Japan and West Germany, with long service life and excellent performance. It is a good helper for your production! Welcome to inquire!

相关标签: