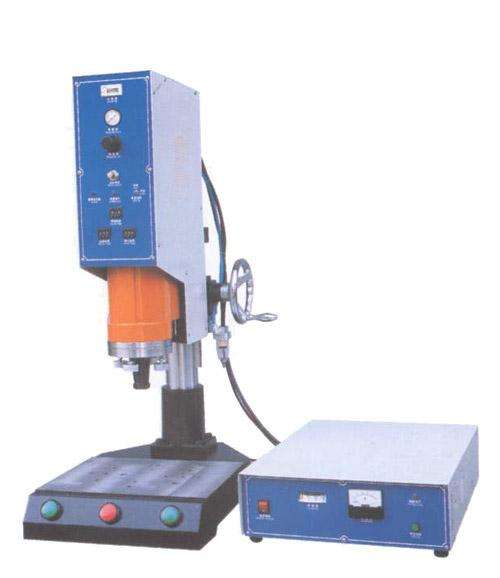

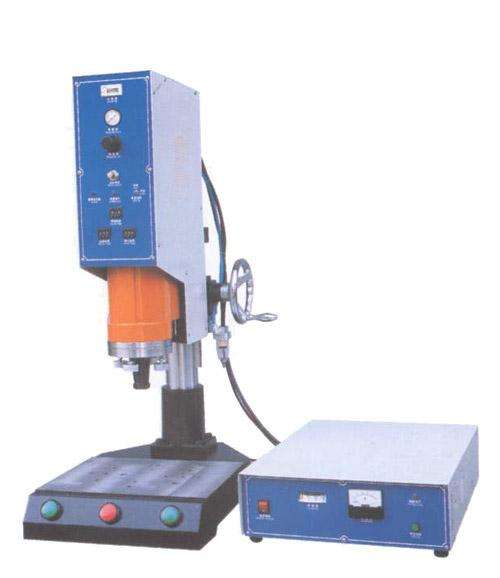

When we use ultrasonic plastic welding machine, in order to get the quality of the product, it is very important to keep the output power stable, because if the output power can not be stabilized, the direct result is that the machine can not obtain stable frictional heat, visible Stable output power is very important, then how can we get the ultrasonic plastic welding machine to obtain stable output power? Mainly need the following four aspects: the output power of the machine, the expansion ratio of the ultrasonic welding head, the air pressure source, the voltage source.

First, there is a formula like this: the actual available power = ultrasonic plastic welding machine output power + ultrasonic welding head expansion ratio. According to the formula, we can see that for a particular machine, the greater the output power of the ultrasonic plastic welding machine, the smaller the HORN expansion ratio; the reverse is also the same. We need to get a stable output power, not to say that only the larger the power, the better, but should choose the right amount of power according to the characteristics of the material to maintain its stable output.

Second, according to the available resources, the engineer makes reasonable design. The available resources mainly include: existing equipment, product quality requirements, product positioning and material. This is because some device resources are fixed, and product design skills are needed to match existing device resources.

Third, the ultrasonic plastic welding machine pay attention to the cooperation of air pressure and voltage. According to experience, such things often occur, when the working time does not reach the quality standard, but after the end of work, the use of voltage and air pressure to achieve the quality standard; When using both voltage and air pressure, automatic inflation of the air compressor air storage cylinder when the air pressure is too low often leads to product errors.

Therefore, in order to get a stable output power, you need to pay attention to the following aspects:

1. The engineer must have a complete understanding of the performance of the ultrasonic plastic welding machine.

2. Understand the performance of the required products,

3. Have a comprehensive understanding of the correspondence between ultrasonic and product fusion.

4. Use power supply voltage regulator and stable compressed air.

Mobile web site

Mobile web site